Aston Martin Works is the home of a great British automotive marque. This month, one of the greatest supercars they have produced is celebrating its 20-year anniversary: the original V12 Vanquish.

In 2001, the V12 Vanquish made its debut in front of eager audiences at the Geneva Motor Show. It immediately made an impact as the newest, most sophisticated, and most technologically advanced automobile designed, developed, and presented by Aston Martin.

The V12 Vanquish was given the most cutting-edge technologies like the F1©-style finger-tip controlled gearshift paddles and drive-by-wire throttle control. Almost overnight, the Newport Pagnell-manufactured V12 Vanquish became the flagship model of Aston Martin.

Expert media critics were immediately enamored by the V12’s beautiful design, exceptional power, and unparalleled performance.

Motortrend in the United States claimed, “Aston Martin’s new Vanquish is one of the most superbly designed front-engine GTs of all time.”

A British magazine, evo, added, “It devours the straight bits with relish, but it also has a ravenous appetite for corners.” The Sunday Times hailed it as “an automotive masterpiece”.

Today, Aston Martin Works President Paul Spires stated, “The original V12 Vanquish represented an important and timely development for our marque. It was, and is, a great super GT with all the character, style and power that is rightly expected of an Aston Martin sports car. 20 years on from that debut, the V12 Vanquish remains a proud part of the marque’s heritage which we celebrate here at Newport Pagnell. It is an exceptional piece of our history, and a car that we can rightly look back on with considerable pride.”

The Origin Story

The story of the V12 Vanquish started years before it made its historic debut at the 2001 Geneva Motor Show.

The V12 started with a concept sports car dubbed “Project Vantage”.

The concept car has been in development throughout the mid-90s and in 1998, it made its debut at the Detroit Motor Show. Project Vantage was designed by then styling chief Ian Callum.

It featured a new 6.0-liter V12 engine that had an output of 460 bhp. The engine was mated to an F1©-inspired paddle shift gearbox. The V12 was given an aluminum tub and composite body panels which was then a huge leap in terms of design and technology for the luxury marque.

Aston Martin continued to develop the program. By autumn of 2000, a group of key media people was allowed to see a pre-production V12 Vanquish, which was clearly greatly influenced by the Project Vantage.

V12 Vanquish design and body engineering

The two-door sports car’s elegant and classic body was designed by Ian Callum, and it was created to embody the tradition, pedigree, and heritage of Aston Martin. Offered in 2+0 or 2+2 configurations, it was seen as bold and dynamic, with finely detailed features that can be seen in the interior and exterior of the car.

All the design elements were carefully considered and incorporated into the car to showcase the marque’s commitment to quality and craftsmanship.

Some of the key features of the car are the bold and distinct auxiliary driving lamps and front direction turn indicators, in between them is the distinct radiator grille and lower air intake which are the marque’s design signature at the time. The front wings and bonnet panels were also given finely detailed compound curves that sweep back to the steeply raked windscreen pillars and low curving roof line.

Adding visual appeal are the sculptured sill and door panels. The rear wheel arches prominently and the rear spoiler and short tail section in the boot lid matches the overall classic look of the V12 Vanquish.

All the exterior body panels were made from aluminum, and each individual panel were tailored manually to the central structure.

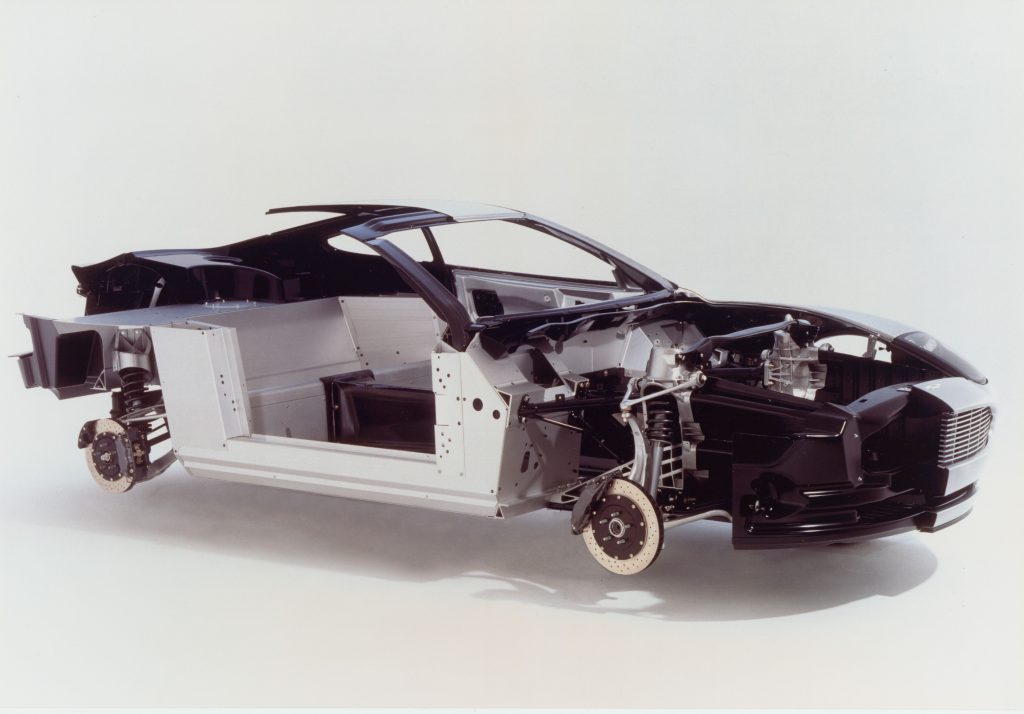

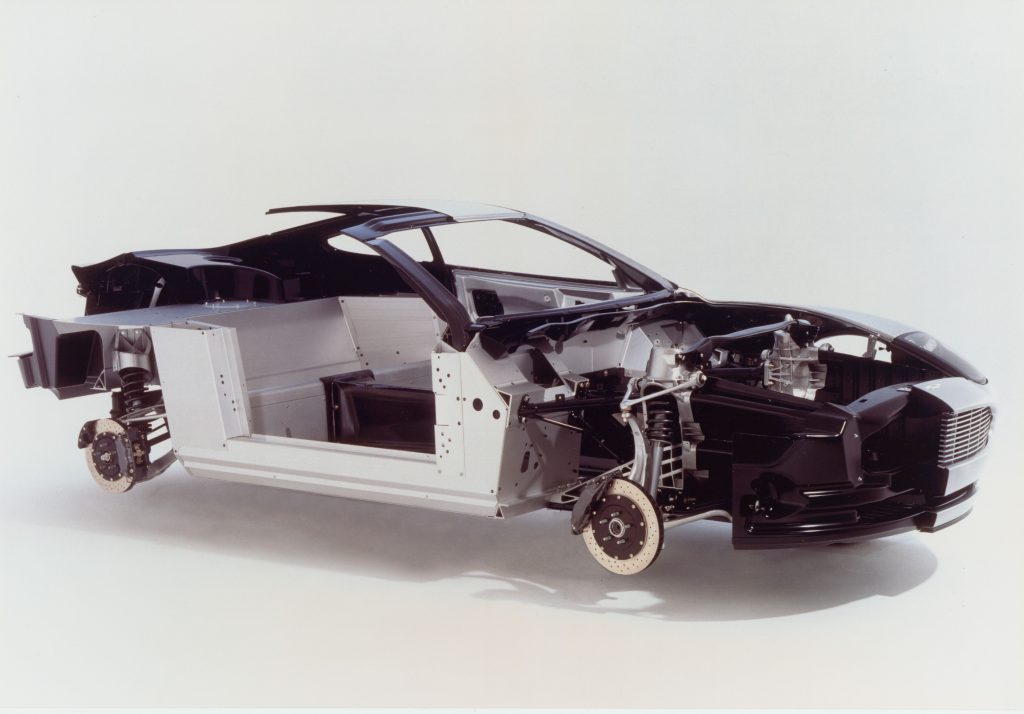

The central transmission tunnel was made completely from carbon fiber while the body structure bonded to it, including the front and rear bulkheads and the floor, were made from extruded aluminum structure.

To create a high strength safety cell, they connected to the central structure a single piece composite inner body side section with carbon fiber windscreen pillars.

To create the structures, they needed a precise, computer-controlled manufacturing process and this was a huge manufacturing undertaking for Aston Martin at the time. These were developed in California’s Silicon Valley in Cupertino and at the University of Nottingham in the United Kingdom.

In front of the driver and passenger compartment is a steel, aluminum, and carbon fiber subframe that houses the engine, transmission, and front suspension which are bolted directly to the front bulkhead. In front of the engine and front suspension is the deformable composite structure that carries the distinct Aston Martin mesh air intake grille. It not only adds crash protection, but it also accommodates the engine, transmission, and air conditioning radiators and intercoolers.

They also developed a completely flat surface for the underbody to allow air to be channeled into a Venturi section at the back to assist high speed aerodynamics.

The composite floor, parcel shelf, and side rails of the luggage compartment were also carefully designed at the rear to give additional deformable crash protection along with the extruded aluminum side impact beams that were in the doors.

All the exterior panels of the V12 including the bonnet, roof, boot lid, doors, and front and rear wings were made from “super-plastic-formed” and pressed aluminum. Each individual panel were then manually tailored and bonded at the marque’s Newport Pagnell factory in Buckinghamshire to guarantee a perfect fit and finish.

It takes eight full weeks to build each V12 Vanquish. Initially, Aston Martin targeted to create around 300 cars each year. As demand continued to grow, and the waiting list ran into years, the marque raised the target to build around 500 cars a year.

In the six years that the car was in production, a total of 2,589 V12 Vanquish were produced, with all the versions.

V12 Vanquish engine and gearbox

Under the hood of this powerful car is an all-alloy, twin overhead camshaft 48 valve 6.0-liter V12 engine. It can generate 460 bhp at 6,500 rpm, and 556 Nm of torque at 5,000 rpm, enabling it to run at 190 mph.

The DB7 showed engineering enhancements made on the V12 engine like the new design inlet manifolds, valve gear, camshafts, crankshaft, and a new exhaust system. All these innovations gave an additional seven percent power.

The whole exhaust system and front bulkhead was wrapped in a heat resistant material that was first used and developed for the aerospace industry. This was done to ensure that the body structure was protected from the heat of the engine and exhaust system.

A new engine oil to water heat exchanger sped up and helped the operating efficiency, working together with an ionized gas misfire detection system that continuously monitored all of the engine’s 12 cylinders.

The V12 Vanquish’s six-speed close ratio manual transmission is connected to the electronic drive-by-wire throttle of the car. It is controlled through the twin paddles mounted on the steering column.

The innovative F1©-inspired gearbox was first introduced in the V12 Vanquish and it introduced electronics to the hydraulics for faster gear changes. Leading writer and automotive journalist Jeremy Clarkson famously dubbed this innovation as “flappy paddles”. The manual transmission also had sophisticated electronics that allowed it to operate automatically. It also has an additional program for winter driving conditions.

Aston Martin recently engineered a manual conversion package that they offered to owners through their in-house heritage center and new car dealership: Aston Martin Works.

Since it opened, there have been around 130 original Vanquish models that have been given a manual transmission. On average, around ten cars are sent to Works every year for the process to done.

Brakes, Suspension, and Steering

The aluminum alloy road wheels were fitted with an anti-lock ventilated and drilled 355 mm (front) and 330 mm (rear) diameter Brembo disc brakes. It also had variable ratio power steering and independent front and rear suspension systems which had forged aluminum wishbones and cast aluminum front suspension uprights.

The rear axle had a limited slip differential that worked with an electronic traction control system which sensed potential wheel slippage and automatically decrease engine power. When necessary, it applies the rear braking system. The V12 Vanquish had exclusively designed Yokohama 255/40 ZR 19 front and 285/40 ZR 19 rear tires that had the AML initials. The tires were mounted on 19-inch diameter wheels with 9-inch width front rims, and 10-inch width rear rims. An automatic electronic sensing system monitors each individual tire pressure and temperatures.

V12 Vanquish S – the fastest

In September 2004, the V12 Vanquish S made its world debut at the renowned Paris Motor Show. At the time, it was the fastest production sports car that Aston Martin has released.

It had a recorded maximum speed of more than 200 mph, which was roughly 321 kph. It was equipped with a 6.0-liter V12 engine with 520 hp. The V12 Vanquish S was designed to be even more powerful, complemented by subtle steering and suspension upgrades, as well as a number of interior and exterior style changes.

When it was launched, the Aston Martin Chairman and CEO at the time, Dr. Ulrich Bez simply described the powerful V12 Vanquish S stating, “It is the ultimate high-performance Aston Martin”.

The elegant yet muscular body of the V12 Vanquish S was given subtle but effective changes. The distinct Aston Martin grille was given a more rounded and open appearance for better cooling. It also had an aerodynamic splitter for better high-speed stability. They redesigned the boot lid at the rear to improve aerodynamics, lowering lift and giving it better balance and stability while also adding a high mounted stop lamp. All the improvements allowed the V12 Vanquish S to get an impressive 0.32 Cd figure.

Other enhancements include shorter steering arms and stiffer springs and dampers. The modified steering geometry allowed it to respond 20% quicker than the ‘standard’ Vanquish, and it also resulted in a lowered required input for steering response.

The brakes were also upgraded to accommodate bigger six piston calipers and bigger grooved and ventilated front discs. The rear discs are 2mm bigger for better heat dissipation. They used floating discs to give drivers the feel of a more consistent pedal during heavy breaking. A revised brake pedal assembly reduced travel and improved pedal feel.

Other innovations include the all-alloy, quad-overhead camshaft 48 valve, 6.0-liter V12 engine that increased the power from 460 bhp to 520 bhp (388kW) at 7000 rpm. The torque was also boosted so it can give 425 lb ft (577 Nm) at 5800 rpm.

Improvements on the engine include new cylinder heads with fully machined inlet ports and combustion chambers for better airflow. They also updated the engine mapping and placed new fuel injectors.

V12 Vanquish S Ultimate – the end of an era

In February 2007, Aston Martin announced that they will end new car production at Newport Pagnell. And production stopped until 2017 when the marque developed their successful Continuation program.

This historic announcement in 2007 was marked by the creation of a strictly limited run V12 Vanquish S Ultimate Edition sports cars.

The 40 cars were all made available by special request of their clients who wants to celebrate the last iteration of a highly significant car in Aston Martin’s history.

The cars were given a specific color and trim combination to set these cars apart. The coachwork was given an ‘Ultimate Black’ finish which is a unique metallic shade. For the interior, the cars were trimmed in semi-aniline leather with coarse stitching, leather headlining, and black chrome finish.

Each car also had a personalized sill plaque that displayed its limited-edition number.

Aston Martin also produced a small number of white V12 Vanquish made for the Middle East, along with their European market Ultimate.

Paul Spires added, “Here at Newport we rightly celebrate the heritage of this great British sports car marque, with particular emphasis on icons such as the DB5 which were almost all built in this seemingly sometimes sleepy corner of Buckinghamshire. However, to also be able to lay claim to a ‘modern classic’ such as the original V12 Vanquish is a great honour for us, and I’m sure that in time people will come to view these cars with the same reverence that is afforded to the early DB cars.”