Why Are Outdoor Companies Getting into Denim?; Outdoor Companies Are Getting into Denim. Here’s Why; Is Denim a Good Outdoor Material?

For the longest time, blue jeans were the working man’s pant. Even in its earliest form, denim, which dates back to 18th century Nîmes, France — textile makers there attempted to replicate Italian serge fabric and created serge de Nîmes, shortened to denim — was worn by sailors and tradesmen. Denim and similarly-rugged fabrics like dungaree were always built for manual labor, but it wasn’t until a US drygoods store owner, a Bavarian immigrant named Levi Strauss, joined up with a tailor named Jacob Davis to reinforce a pair of denim work pants with copper rivets that blue jeans as we know them today existed.

That was in 1873, and since then much as changed. Strauss and Davis’ jeans, then called overalls, were built for miners and cowboys. Rivets were critical to their construction because they reinforced the fabric at common points of wear, like the corners of pockets. As jeans grew in popularity in the 1960s and 70s, they entered the mainstream, where durability became less of a necessity. Manufacturers make the fabric thinner, softer and stretchier; they produced different cuts and styles; they ripped them to shreds before selling them. These alterations were for the sake of fashion, not work.

Denim never lost it’s rough edge though. Levi’s, Lee, Wrangler and more have always maintained their stock of blue jeans built for work. In recent years though, the material has caught the eye of a new group: outdoor gear companies. Sometimes these brands angle denim into their lifestyle collections. Others bill it as “performance,” which typically means that they’ve added stretch to the fabric construction with articulating gussets or by blending materials like Spandex or polyester into the cotton. “We wanted to bring a jean to market that spoke to the lifestyle of our customers,” says Mark Little, Patagonia’s Product Line Director of Men’s Sportswear. “This is where the Performance Jean concept came to life. Blending organic cotton with a Coolmax T400 fiber created an amazing textile for the active jean wearer. You get the comfort and durability of cotton denim with the added performance of Coolmax, which provides added breathability and wicking.”

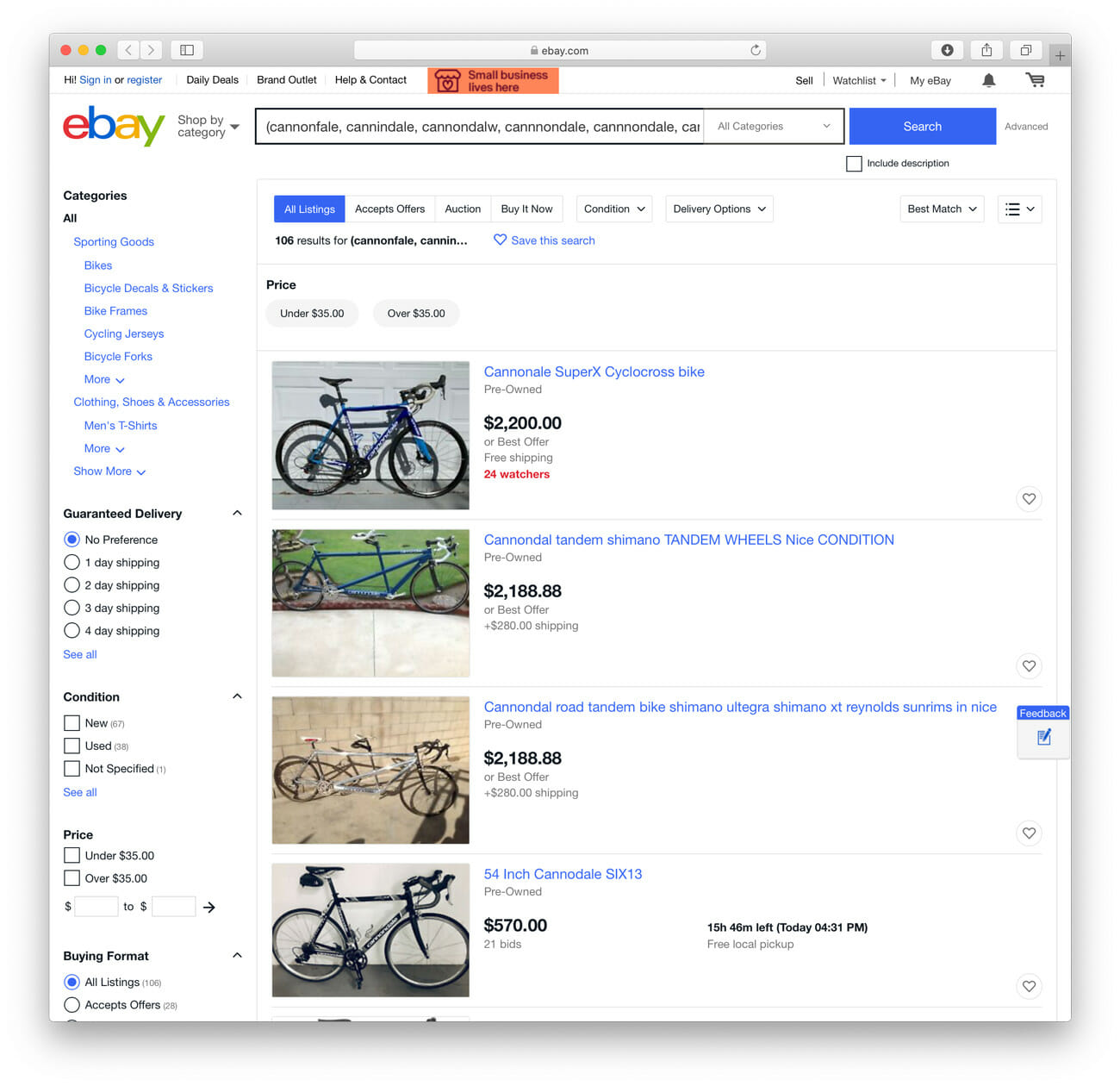

More recently, there’s been a marked increase in the number of new outdoor brands emerging with denim as a foundational, introductory product. Boulder Denim is one such company; it looked at performance outdoor clothing to identify essential qualities and then created its own “top-secret” blend of denim that provides stretch in all direction, maintains its shape afterward and sheds liquid. Meridian Line, an apparel company owned by climber and artist Jeremy Collins, launched its own outdoor-focused stretchy blue jeans on Kickstarter earlier this summer, earning over $300,000.

Backcountry Denim is another company that used Kickstarter as primary propulsion. It only narrowly achieved its $40,000 goal in summer 2017, but its angle on blue jeans is arguably more interesting: its denim, which is produced by Cone Mills in North Carolina, is woven with Dyneema, an ultra-high-molecular-weight polyethylene fiber that’s light enough to float but stronger, by weight, than steel. Backcountry Denim doesn’t specify precisely how much of the stuff runs in its jeans, but it does claim that it makes them 250 percent more resistant to abrasion and tear.

The big guys have taken note. Mountain Hardwear now offers the Crux Denim Jean, a light and stretchy pair of pants explicitly designed with rock climbing in mind and enhanced with Dyneema. And this year, with the sophomore collection of its workwear line, Patagonia debuted Steel Forge Denim — a fabric produced by Cone Mills that’s made of 92 percent organic cotton and 8 percent Dyneema. (Patagonia also addressed the harmful impact of dyeing denim with synthetic indigo by using Tennessee-grown plant-based dye instead.) This new iteration of super-strong denim is designed for work, not mountain climbing, but its introduction brings the fabric full circle and grounds it again in its rugged roots of manual labor.

Durability was important in 1873 when Strauss and Davis designed their denim overalls for the men working in the grasslands and under the mountains, and it’s important now. It’s no surprise that outdoor companies big and small would integrate it into their apparel lines. “It was worn as a second skin to protect from the rigors of a hard day’s work. In outdoor apparel, we are looking for the same things,” says Little. So, is denim an outdoor material? It is; it always was.