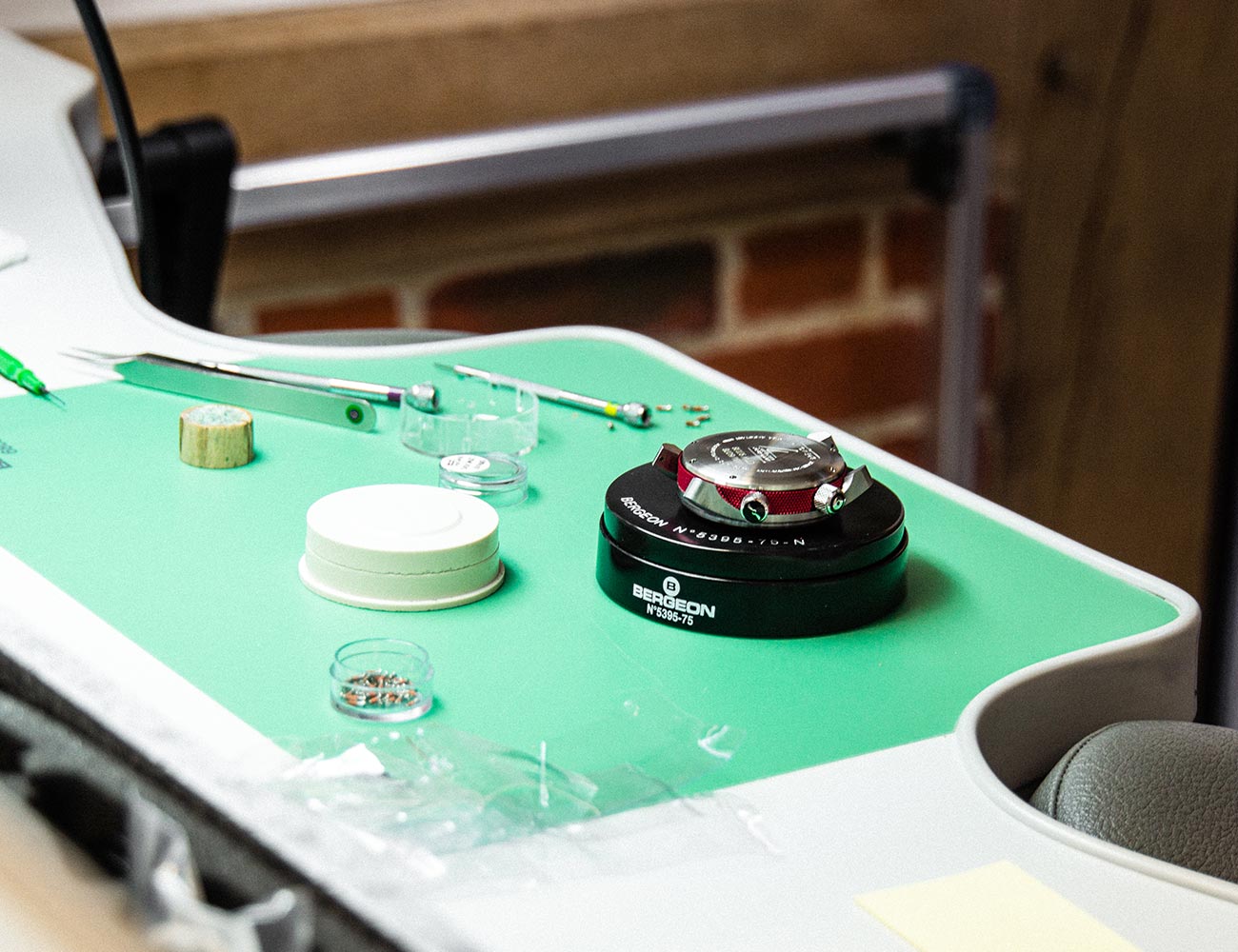

The International Watch Company was established in the mid-1880s by an American operating in Schaffhausen, a German-speaking town in Eastern Switzerland. Though the industrial revolution had already come to pass, fine Swiss watchmaking was still piecemeal labor done mostly in people’s homes. IWC’s founder, Aristo Jones, had a distinctly American vision of an electrically-powered watch factory, and once hydro-electric became established in the area, IWC’s headquarters quickly became one of the most prolific watchmaking facilities in the world, taking on highly profitable commercial and military contracts throughout the World Wars. (See our review of their new facilities here.)

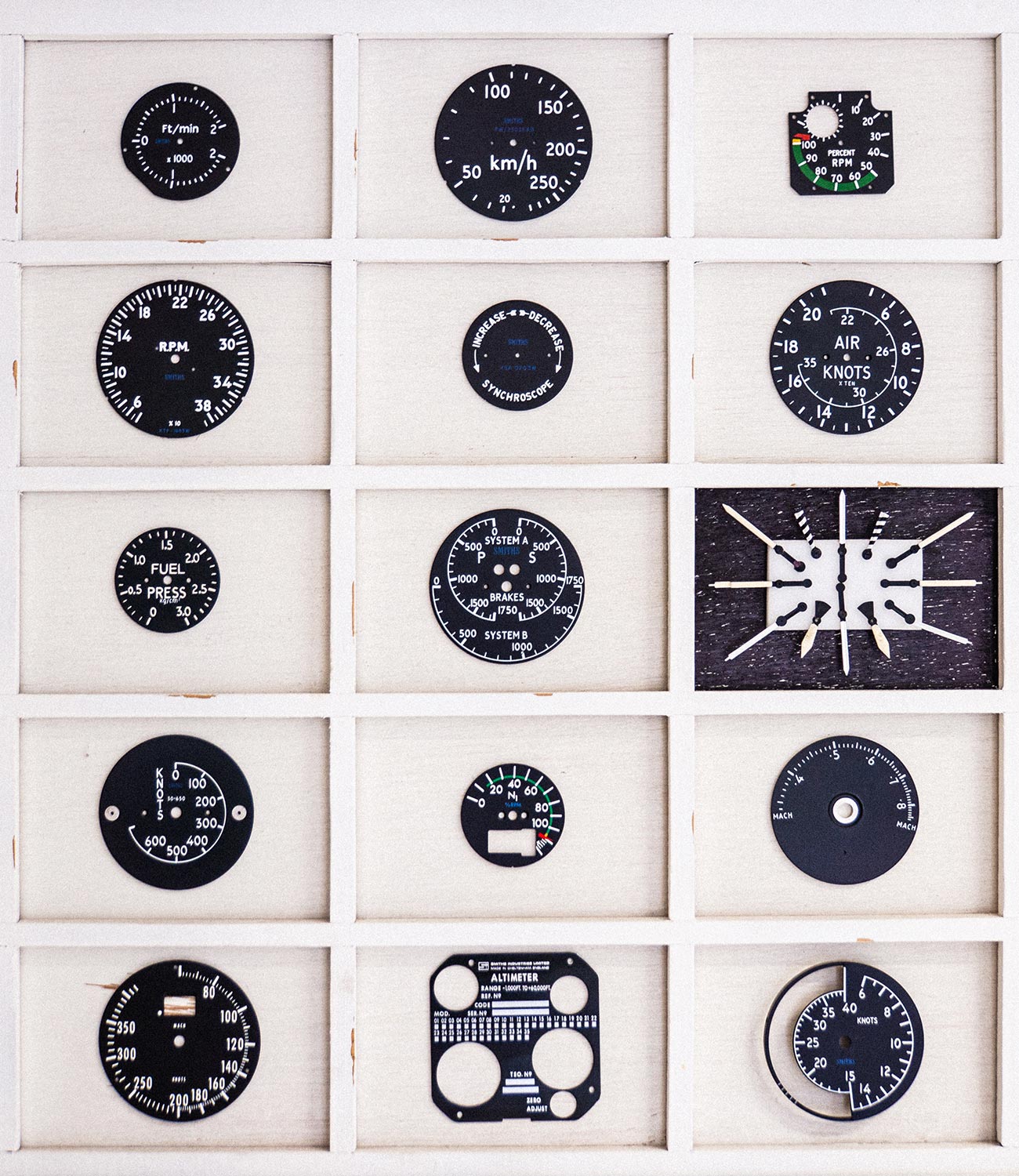

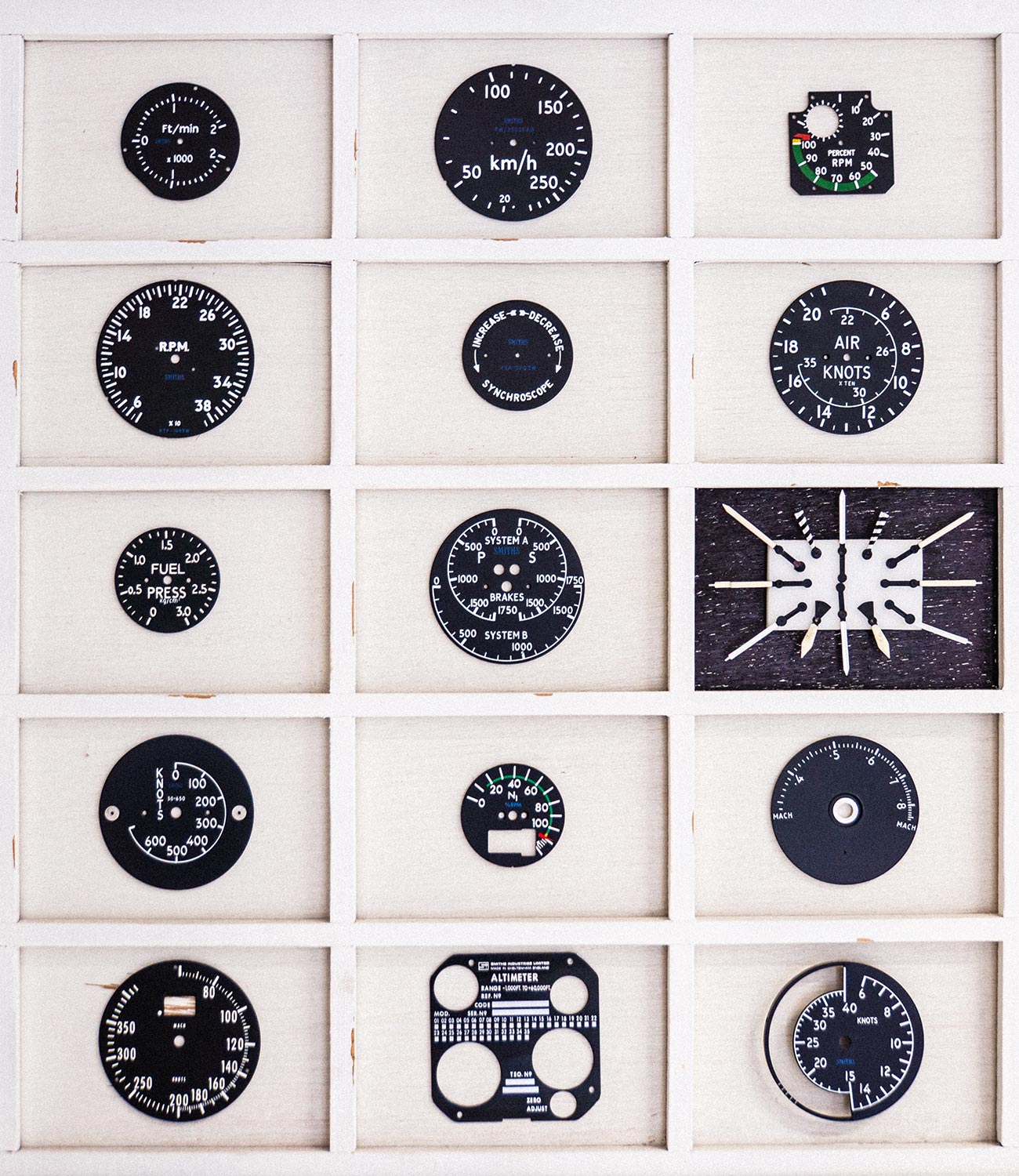

Throughout WWI and WWII, IWC built more mil-spec pilot’s watches than any other company, and the focus on aviation timepieces remains central to IWC today. Their modern catalog also includes dress watches, dive watches, and more than a few grand complications costing hundreds of thousands. Uniquely, IWC’s products span a range far wider than that of many other watch companies, and the quality of their wares is exceptional.

IWC aficionados tend to collect and fuss over the pilot’s watches, and because the company refers back to its historic catalog so much, those in the know love to complain about inconsistencies between older models and their modern iterations. Interestingly, IWC is quick to respond to customer feedback, and few watch companies revise and improve their watches as regularly. Their famous “Mark” series pilot’s watches, for example, have gone through a bufuddelingly large number of iterations, each one seeming to satisfy and disappoint the aficionados in equal measure.

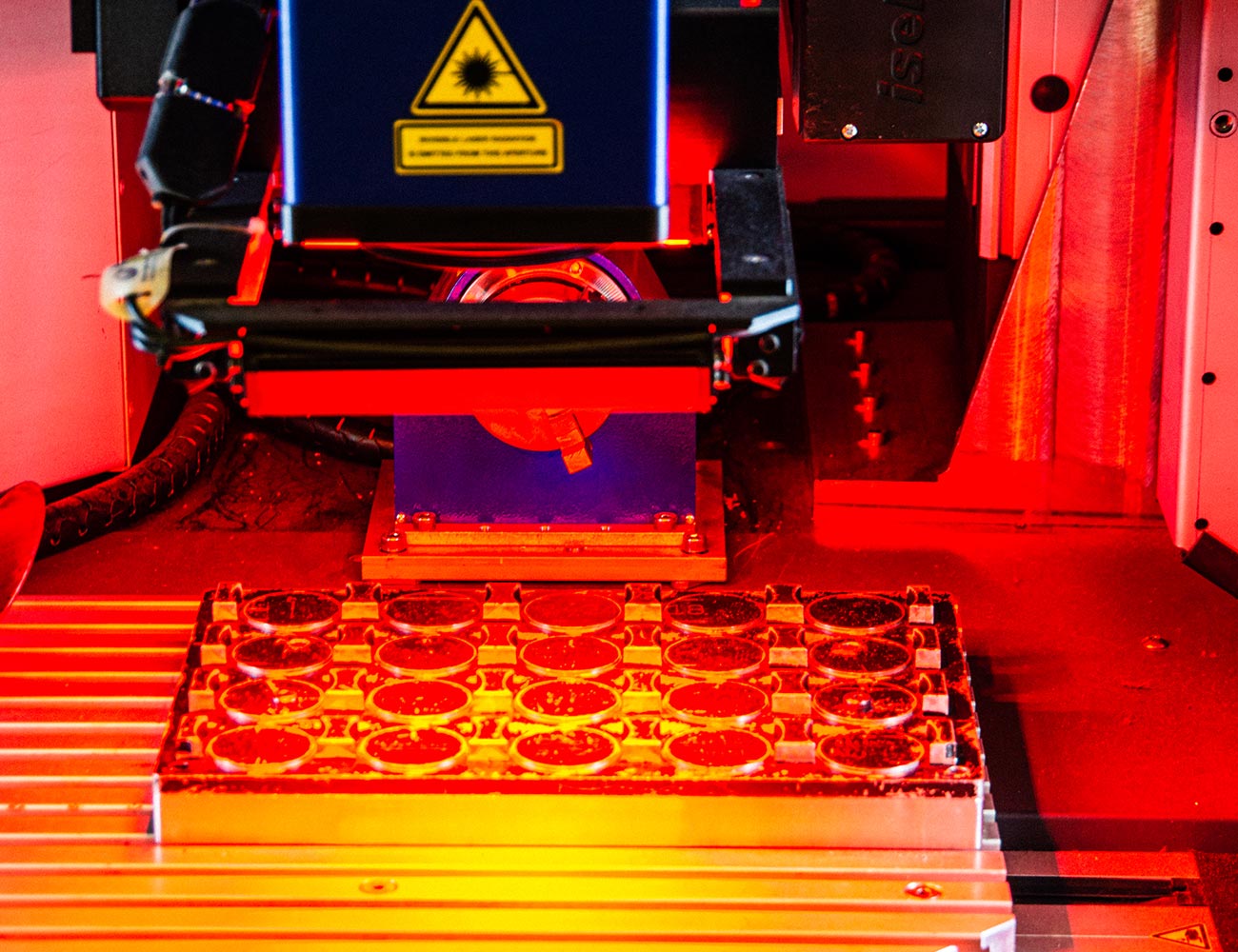

As of this writing, IWC has been slowly replacing 3rd-party movements with in-house calibers in the lower end of their range, and mostly without significant price increases. This evolution makes their current catalog particularly tasty, as the value propositions are getting better every year.

How to Use This Guide

You can read straight through or use the table of contents to jump to specific types of watches.

Table of ContentsPilot’s Watches

Dive Watches: The Aquatimers

The Portugieser

The Ingenieur

The Portofino

The Da Vinci Collection

The Jubilee Collection

Pilot’s Watches

IWC segments their pilot’s watches into five categories: Classic, Spitfire, Top Gun, Le Petit Prince, and Antoine De Saint-Expuéry (author of Le Petit Prince). Within each category you’ll find many of the same watches, differentiated mostly by the dial’s color and case materials. Roughly speaking, here’s how the IWC pilot’s watches break down:

Classic: steel cases, with the occasional titanium case thrown in

Spitfire: largely bronze cases, but some steel as well

Top Gun: ceramic cases

Le Petit Prince: steel cases with blue dials and “Le Petit Prince”-themed case backs

Antoine de De Saint Expuéry: steel cases with brown dials

(Note: Below we take each individual watch model and indicate which series it’s available in)

Mark XVIII Pilot’s Watch

Starting with the now highly collectable Mark XI, IWC has iterated on their most basic pilot’s watch, and this is the one that often causes the most stir among the aficionados. Placement of the date window has caused feuds among forum-dwelling nerds, but that passion indicates how compelling the Mark series pilot’s watches are.

Diameter: 40mm

Movement: Cal. 35111 (based on Sellita SW300-1)

Available Series: Classic (black, white, and a heritage colorway); Le Petit Prince; Spitfire; Antoine De Saint Expuéry

Price: $4,250 (strap)-$5,250 (bracelet)

Pilot’s Watch 36

Following the vintage trend, IWC’s 36mm pilot’s watch is a unisex model ready for just about any wrist.

Diameter: 36mm

Movement: Cal. 35111 (based on Sellita SW300-1)

Available Series: Classic (gray, black, or blue dial)

Price: $4,150 (strap)-$5,150 (bracelet)

Pilot’s Watch Chronograph

A little bigger and featuring a weekday and date complication alongside a robust three-register chronograph function, this watch is a purebred IWC staple.

Diameter: 43mm

Movement: Cal. 79320 (based on ETA 7750)

Available Series: Classic (white, racing green, black, or gray dial); Le Petit Prince (blue dial with steel or gold case); Antoine De Saint Expuéry (brown dial)

Price: $5,150 (strap)-$22,200 (gold)

Big Pilot’s Watch

With its enormous dial, clever power reserve indicator at 3-o’clock, and unmistakable “onion” crown, the Big Pilot’s Watch is perhaps IWC’s most iconic timepiece, one that could stand for the brand above all others.

Diameter: 46.2mm

Movement: Manufacture cal. 52110 with 8-day power reserve

Available Series: Classic (black dial with steel, titanium, or bronze case),;Le Petit Prince (blue dial with steel case); Spitfire (gray dial, gold case)

Price: $12,900 (steel)-$13,200 (titanium or bronze)

Complicated Big Pilot’s Watches

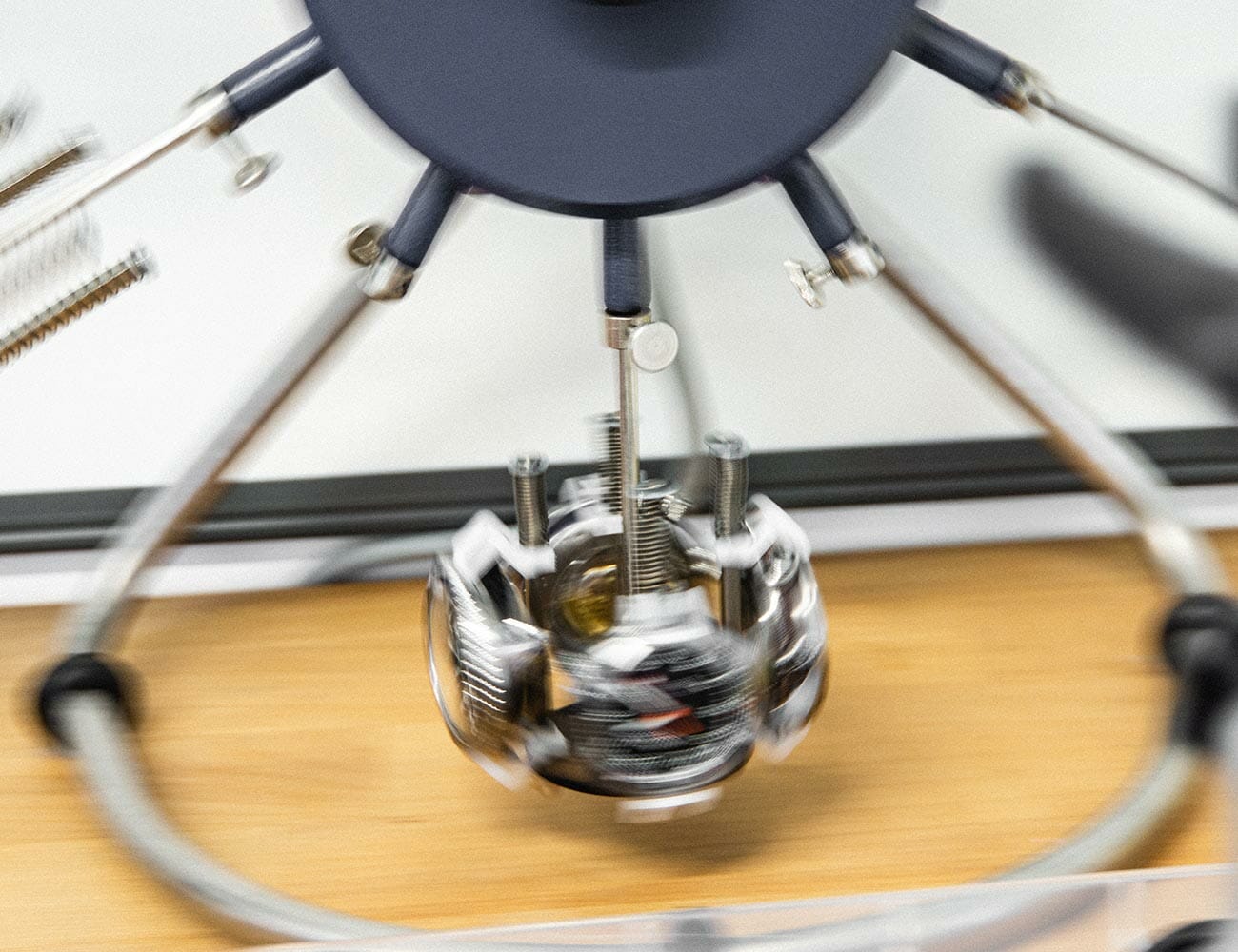

Using the same basic format as the Big Pilot’s Watch, these watches include elaborate in-house movements of the highest horological quality. There’s a big-date, an annual calendar, a perpetual calendar, a dual-register, right- handed model, and a constant-force tourbillon.

Diameter: 46.2mm

Movement: Various in-house calibers with complications

Available Series: All except Top Gun

Price: $14,700+ (unlisted for Tourbillion model)

Timezoner Pilot’s Watch

No pilot’s watch collection is complete without a serious world timer, and the relatively new addition of the Timezoner model sees IWC taking global travel seriously (this was less of a concern back in the short-flight days of the World Wars). This watch will track a second time zone as well as the time in cities around the world.

Diameter: 46mm

Movement: Manufacture cal. 82760

Available Series: Classic; Spitfire; Antoine De Saint Expuéry

Price: $11,900+

A Few Other Smaller Pilot’s Watches

There are a few unique yet simple pilot’s watches from IWC, including the 41mm Top Gun in carbon, a 39mm UTC Spitfire in bronze, and a 39mm time-date Spitfire in steel or bronze.

Diameter: 39-41mm

Movement: Manufacture cal. 32100 (time and date); Manufacture cal. 82710 (UTC)

Available Series: Spitfire; Top Gun

Price: $4,450+

A Few Other Larger Complicated Pilot’s Watches

These models show up in the Top Gun and Classic series of watches, and are just unique enough to warrant a separate entry. The blacked-out Dual Chronograph with its split-second function from the Top Gun collection carries the unique 79420 in-house calibre, while the AMG Mercedes chronograph with carbon dial and the Blue Angels edition of the same chronograph use the Cal 89361 in-house movement.

Diameter: 44mm (Dual Chronograph) 44.5mm (dual-register chronographs)

Movement: Manufacture cal. 79420 (Dual Chronograph); Manufacture cal. 89361 caliber (dual-register chronographs)

Available Series: Top Gun; Classic

Price: $10,900 (Blue Angels); $14,600 (Dual Chronograph); $15,600 (AMG Mercedes)

Dive Watches: The Aquatimers

Flying far below the radar, these submersible divers from IWC are robust timepieces with compelling features and a look that imitates nothing while remaining quite classic. The internal rotating timing bezel is actuated via the crown at 9-o’clock, a feature which, taken visually, offers a unique symmetry to these waterproof watches.

Aquatimer Automatic

If the time, date and a rotating timing bezel are all you’ll need, then the Aquatimer Automatic is the watch for you. With 300 meters of water resistance, these watches are more than ready for any watery adventure.

Diameter: 42mm

Movement: Cal. 30120 (based on ETA 2824-2)

Price: $5,400 (rubber)-$6,400 (bracelet)

Aquatimer 2-Register Chronographs

With the date, running seconds, and a minute totalizer, these chronographs bring a bit of the pilot’s watch line down underwater with them. There are three special editions: Charles Darwin (our favorite, in bronze), Galapagos Islands (blacked-out), and the Laureus Sport for Good (one of the not-for-profit charities that IWC supports, this edition carries a lovely blue colorway).

Diameter: 44mm

Movement: Manufacture cal. 89365

Price: $10,600-$11,700

Aquatimer 3-Register Chronographs

Add in the day of the week and an hour totalizer, and you’ve bumped up a notch in the IWC diver’s selection. However, these models do not house in-house movements, so some may prefer the 2-register model above, while others may prefer the always-serviceable ETA 7750 Chronograph movement in this watch. There is also a lovely Jaques Cousteau limited edition available.

Diameter: 44mm

Movement: Cal. 79320 (based on 7750)

Price: $6,850 (rubber)-$7,850 (bracelet)

The Portugieser

Based on oversized timepieces developed in the 1930s for two Portuguese merchants, these watches range in price from $7,600 to $235,000+ for grand complications, indicating that IWC is not only committed to this platform, but that the Portugieser covers a lot of ground for their customer base. A closer look explains why.

The Portugieser Chronograph

It’s the lack of date that creates such a compelling and open dial on these no-nonsense chronographs, which so often have the date squished in under the assumption that the function outplays the aesthetics. Water resistance is 30 meters, so don’t do any cannonballs in this one.

Diameter: 40.9mm

Movement: Cal. 79350 (based on ETA 7750)

Price: $7,600 (steel)-$16,600 (gold versions)

Portugieser Chronograph Classic

Step up into the in-house cal. 89361 movement, and you’ll pick up a date complication and a dual-hand sub-dial at 12 o’clock that totals both minutes and hours when you run the chronograph function. Running seconds are elegantly displayed on the 6-’o’clock sub-dial. Water resistance is still 30 meters, so go easy on this one around the water.

Diameter: 42mm

Movement: Manufacture cal. 89361

Price: $12,100-$20,100 (gold)

Portugieser Automatic

A straight-forward watch that packs a ton of mechanical umph. The left-hand sub-dial tracks running seconds while the right-hand sub-dial indicates how much of the 52010 movement’s 168 hours (7 days) of power are stored up. That’s correct: set it down for a week at a time without having to reset it.

Diameter: 42.3mm

Movement: Manufacture cal. 52010

Price: $12,700-$23,900 (gold versions)

Portugieser Annual Calendar

A complication that reaches toward haute horlogerie while barely breaking the $20k barrier. The 7-day power reserve makes sure you don’t have to go resetting all of those complications should you go with another timepiece for sportier adventures.

Diameter: 44.2mm

Movement: Manufacture cal. 52850

Price: $20,900-$31,000 (gold)

Portugieser Perpetual Calendar

A classic complication that includes a moon-phase indicator, this watch plays nicely into the Swiss horological tradition with an appearance that’s clean but full of information. Precious metals only, so the prices are high.

Diameter: 44.2mm

Movement: Manufacture cal. 52615

Price: $38,000 (red gold); $41,100 (white gold)

Portugieser Grand Complications

These watches will take you far higher up the horological food chain than even the most complicated pilot’s watches from IWC. Prices start at $86,500 for the gold minute repeater (not a crazy price tag, given what it is) and soar to unlisted prices. IWC shows their unique breadth with these fascinating and beautiful timepieces.

Diameter: Various

Movement: Various in-house

Price: $86,000+

The Ingenieur

After Audemars Piguet and Patek Philippe hired Gerald Genta during the 1970s to design the now-famous Royal Oak and Nautilus steel sport watches, IWC brought the famed designer into its fold to help them compete in this fast-emerging market. The result was the Ingenieur, a watch that never gained the fame of either the Royal Oak or the Nautilus. And yet, for those seeking a sporty-yet-dressy watch that’s 100% IWC, the Ingenieur is accessible, handsome, durable, and incredibly versatile.

Ingenieur Automatic

Straight-forward, water resistant to 120 meters, rugged enough for an adventurous weekend and classy enough for suit-and-tie affairs, this watch may be the best deal in IWC’s whole catalog.

Diameter: 40mm

Movement: Cal. 35111 (based on Sellita SW301-1)

Price: $4,590 (steel on leather)-$13,600 (red gold)

Ingenieur Chronograph

If the Omega Speedmaster is too sporty for you, consider the Ingenieur Chronograph, a watch that nimbly conveys all the information of a chrono with tachymeter scale while still maintaining an elegant visage and a plain bezel. Inside is an in-house movement that one would expect to pay much more for.

Diameter: 42.3mm

Movement: Manufacture cal. 69375

Price: $7,950 (steel on bracelet)-$18,100 (red gold)

Ingenieur Perpetual Calendar with Digital Date Month

It seems IWC can’t help but flex their horological muscle, even when executing their presumably more affordable lines of watches (of which, to be fair, this is not). This watch carries a full chronograph function and a fascinating large date and month display on sub-dials at 9 and 3-o’clock.

Diameter: 45mm

Movement: Manufacture cal. 89801

Price: $46,300

The Portofino

The Italian seaside town of Portofino is so elegant and beautiful that when the equally elegant and beautiful Cate Blanchett walks the red carpet wearing an IWC Portofino, we confront a self-referential, kaleidoscopic display of luxury. Grab a shard of that impossibility and strap it to your wrist with the Portofino.

The Portofino Automatics

Simple, elegant, and unmistakably IWC in character, the Portofino Automatic is available in an array of beautiful dial colors and case metals.

Diameter: 34mm; 37mm; 40mm

Movement: Cal. 35111 (based on Sellita SW301-1); Cal. 35100 (34mm)

Price: $4,700 (steel)-$11,600 (gold versions)

The Portofino Chronograph

If a little more complication is your dish, check out the Portofino Chronograph models. With a day-date complication and three elegantly proportioned subdials, this watch confidently displays its pedigree.

Diameter: 42mm

Movement: Cal. 75320 (based on ETA 7750)

Price: $5,800 (steel)-$15,300 (gold versions)

Portofino Hand-Wound 8-Days

An in-house movement with a huge power reserve packed into a classic-looking watch that will never go out of style.

Diameter: 45mm

Movement: Manufacture cal. 59210

Price: $9,900 (steel)-$18,800 (gold versions)

Portofino Automatic Moonphase

A classic and dreamy complication for a classic and dreamy watch. Smartly, IWC doesn’t use an in-house movement here, so the price of entry is relatively achievable.

Diameter: 37mm; 40mm

Movement: Cal. 35800 (based on Sellita SW300-1)

Price: $6,900

Portofino Hand-Wound Moonphase

Well, if you must have an in-house moonphase watch, then this is the ticket. Baiscally their 7-day movement with a moonphase complication added in, this timepiece is just complicated enough to warrant genuine horological fascination.

Diameter: 45mm

Movement: Manufacture cal. 59800

Price: $13,000 (steel)-$22,900 (gold case, grey dial)

Portofino Retrograde Tourbillon

This watch is the granddaddy of the Portofino lineup and sees IWC really flexing their watchmaking muscle. A retrograde date complication powered by a very complicated tourbillon escapement adds up to a uniquely interesting high-end watch.

Diameter: 45mm

Movement: Manufacture cal. 59900

Price: $58,000

The Da Vinci Collection

For an American-founded company operating in Switzerland, IWC sure does seem to love the Italians. The DaVinci series watches step up the jewels and complications to a degree that spans, again, an incredibly wide range of features, luxury, and price. As such, the pilot’s watch aesthetics are not to be found here.

DaVinci Automatic 36, 36 Moonphase, and 40mm Automatic

Aimed at those who prefer classic European cues of femininity, the 36 is offered in a wide array of styles that range from simple to the very edge of flamboyance. For the gentleman seeking fantastical elegance, the 40mm will fit the bill.

Diameter: 36mm; 40mm

Movement: Cal. 35111 (based on Sellita SW300-1)

Price: $5,400 (steel on leather)-$37,900 (gold with diamond bezel)

DaVinci Complications

Don’t think that IWC isn’t going to pack their most complicated movements into their most elegant watches. Here we have a limited edition chronograph, a perpetual calendar chrono, and a retrograde tourbillon.

Diameter: 42mm (chronograph); 43mm (perpetual calendar); 44mm (retro tourbillon)

Movement: Various in-house

Price: $12,700+

Jubilee Editions

Not exactly another series of watches, but to celebrate 150 years of business, IWC has released myriad Jubilee editions that range from pilot’s watches to their most complicated and bejeweled specimens. Sizes, complications and styles range widely, and we encourage you to snoop around the Jubilee page to see what’s still available at any time.

Note: Purchasing products through our links may earn us a portion of the sale, which supports our editorial team’s mission. Learn more here.